Introduction :

This machine unit are special design for packing small sauce product like ketch up , chili sauce ,Fish meal and so on .The machine can automatic make the bag ,weighing the product ,filling product in to bag and then output the conveyor .The whole machine are control by PLC and can operate on Touch screen .Easy for adjusting and maintain .

| ZL900 vertical bag forming filling packaging machine |

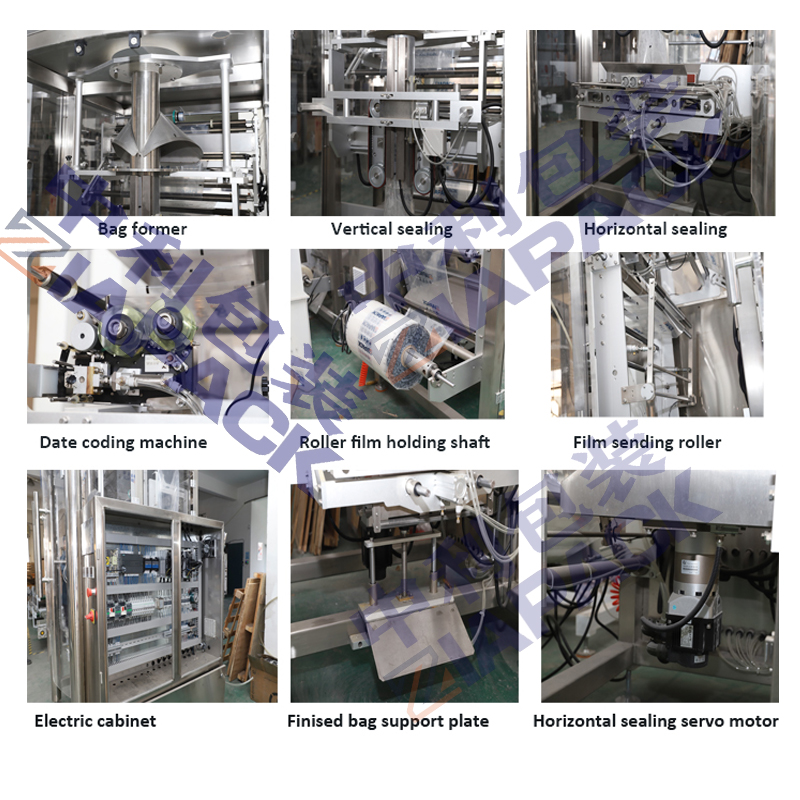

| Machine fully controlled by Siemens PLC & Touch-Screen |

| Minute capacity can automatic display on Touch screen |

| Film transport system and horizontal Jaw motion both drive by Panasonic |

| Safe quick change of tube and collar for different size bag |

| Optoelectronics detect film position on collar to correct film excursion |

| Electrical photo sensor inducting color code to control bag length |

| Unique Pneumatic Film-Reel locking structure to avoid film drawing deflecting |

| Independent temperature adjustment. |

| Date coding by ribbon |

| Various types of heating sealable laminated films namely PE/BOPP, CPP/BOPP, CPP/PET, PE/NYLON, aluminum foil based can be run on the machine. |

| Material contact part made by SUS304(Can made by 316) |

Technical parameter for whole line :

| Bag type | Pillow bag |

| Maximum Capacity | up to 20kilograms |

| Minimum Capacity | 5kg |

| Speed | 3-5ag/min depend on the product |

| Weighing accuracy | ±0.5-1% dependent on products characteristics |

| Bag Length | 400 to 700mm |

| Bag Width | 200-430mm |

| Reel Film Width | ≤900mm |

| Film thickness | (80-150mic.) |

| Reel Outer Dia. | 600mm |

| Reel Inner Dia. | 75mm |

| Voltage | AC380V/50-60Hz, 3phase |

| Compressed Air Requirement | 0.8 MPa0.36 M3min |

| Total powder Consummation | 15kw |

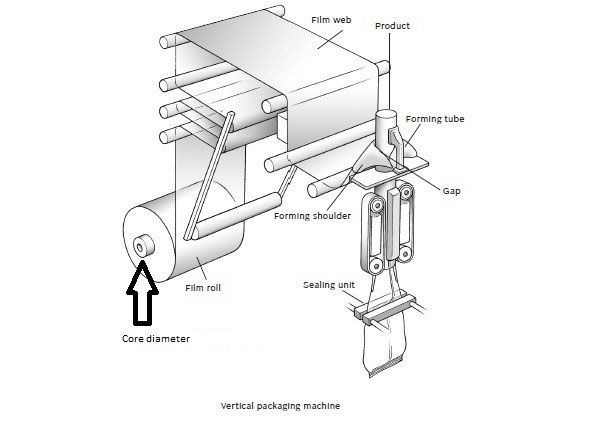

Bag forming process: