Applications

Pre-made pouch fill and seal machine, composed of 8 working stations of efficiency and stability, emphasizes the package of stand-up bag, zipper bag, spout bag, and various pre-made pouches. Cooperated with different dosing systems (combination weigher/ linear weigher/ auger screw/ piston filler) and automatic lifting conveyors, it is widely applied to granules, liquid, and powder.

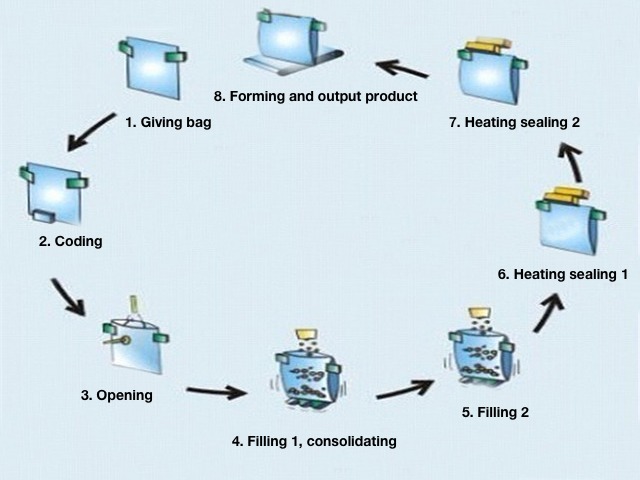

Working Stations

Some of the working stations in the left sketch are optional and

customizable.

Take zipper bag as an example as below:

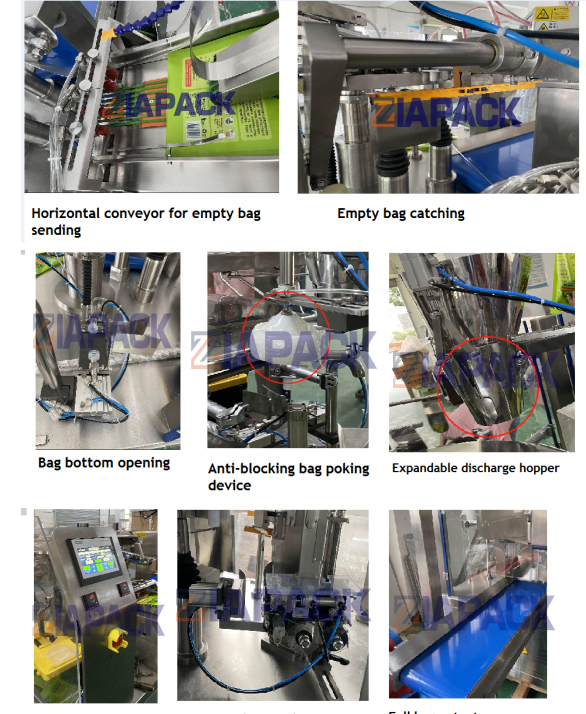

1st bag feeding station

2nd code printing station

3rd zipper opening station

4th product filling and vibrating station

5th zipper closing station

6th buffering and dust cleaning station

7th bag sealing station

8th bag forming and outputting station

Features

- Equipped with dosing system to achieve precise product measuring and filling

●Assembled with elevator to lift material automatically

●SIEMENS PLC and touch screen, easy for operation

●Schneider frequency converter and SMC cylinder

●Full 304# stainless steel construction, able to be cleaned by rinsing

●Self-diagnosis: no filling or sealing when it is detected that the bag is not open or not open completely or when there’s lack of bags

●Auto-alarming or stop if there’s something wrong with the air pressure or heating

Technical Data

| Model | ZG8-200 |

| Working Stations Number | Eight |

| Pre-made Pouch Types | Heat sealable premade side seal bags, like gusseted bag, flat bottom bags, zipper bags, stand-up bags, spout bags, etc. |

| Pre-made Pouch Size | Width: 80 to 220mm (3.15” to 8.66”) |

| Length: 100 to 300mm (3.94” to 11.81”) | |

| Capacity | 35 to 40bpm (depending on product and pouches) |

| Filling Range | 10 to 2500g (depending on the product) |

| Power Consumption | 2.5kw |

| Air Consumption | 0.6 m³/min (supplied by the user) |