Introduction of the solution :

This production line including One set ZL4-1000 Four bucket linear weighing machine .One set ZL520 Vertical bag forming filling sealing ,one set Z type bucket elevator and one set platform and ladder . The whole machine can automatic measuring small granule product and packing into roll film bag .Widely use for packaging rice bean sugar chips and so on

Features of weighing system

- Adopt high precision and high accurate loadcell of famous brand, resolution is improved up to 2 decimal;

- Program recovery function can reduce operation failures and support multi-segment weight calibration;

- No products auto pause function can improve weighing stability and accuracy;

- 100 programs capacity can meet various weighing requirements and user-friendly help menu contributes to easy operation;

- Linear amplitude can be adjusted independently in the running;

- Many languages available for global markets.

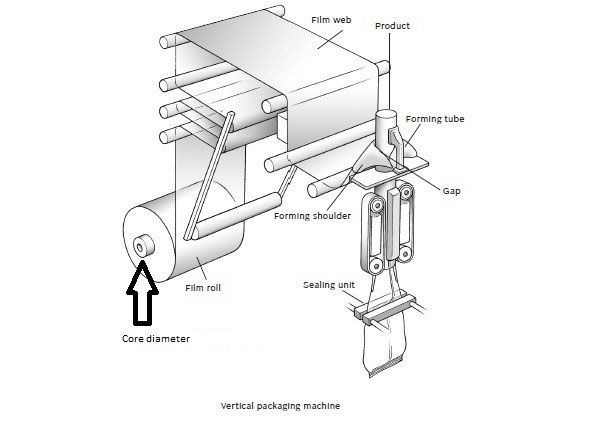

ZL520 vertical bag forming filling sealing Packaging machine

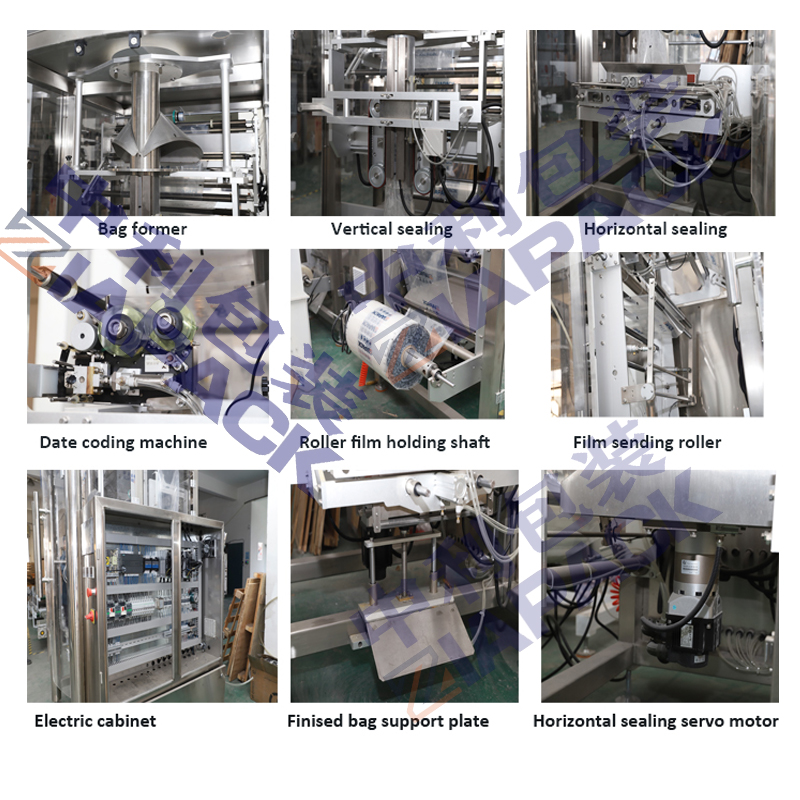

The whole machine made by Stainless Steel 304, This machine equipped with bag-making, cutting, code printing , etc. Siemens PLC and Touch Screen,Panasonic servo motor, Japanese Photo Sensor , Korean Air valve, etc..

The film pulling system adopted servo motor driving making speed faster .

Technical Parameters:

Weighing Range: 30-500g

Packaging Speed:40-55 bags/min

Bag size: (80-360)*(100-260)mm(L*W)

Compressed air requirement: 0.6Mpa 0.65m³/min

Reel outer diameter: 400mm

Core inner diameter: 75mm

Machine weight: 600kg

Power source: 4.5kW 380V±10% 50Hz

Detail function :

Main Features and Characteristics:

A wide range of pouches: Pillow and Gusset pouches(optional).

High speed: 20-50 bags/min

Easy to operate: PLC controller and color touch-screen, fault indication on the touch screen.

Easy to adjust: only about 10 minutes to change different pouches.

Frequency control: speed can be adjusted by frequency conversion within the range.

High Automation: unmanned in weighing and packing process, machine alarm automatically when failure.

Safety and Hygiene:

No film, machine will alarm.

Machine alarm and stop when the inadequate air pressure.

Safety guards with safety-switches, machine alarm and stop when the safety guards are opened.

Hygienic construction, the product contact parts are adopted sus304 stainless steel.

Suit material