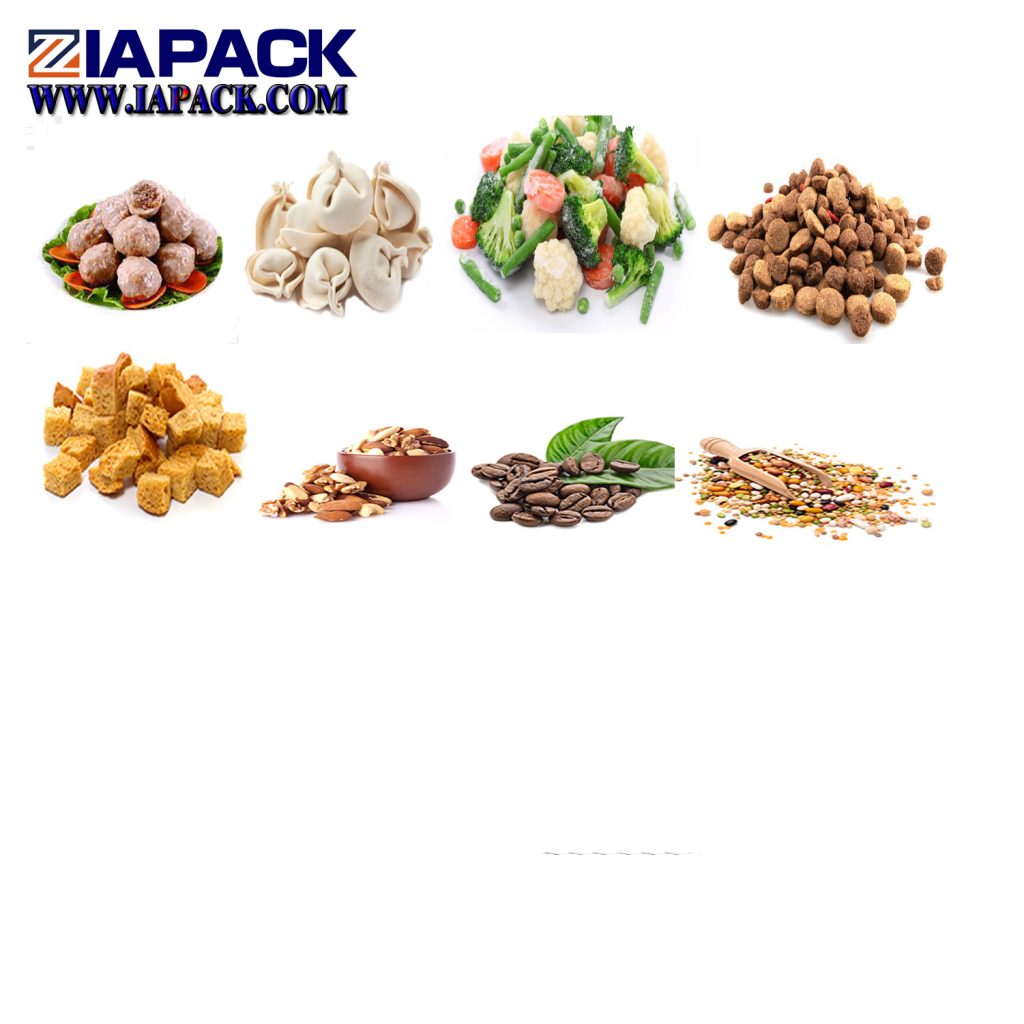

Applications

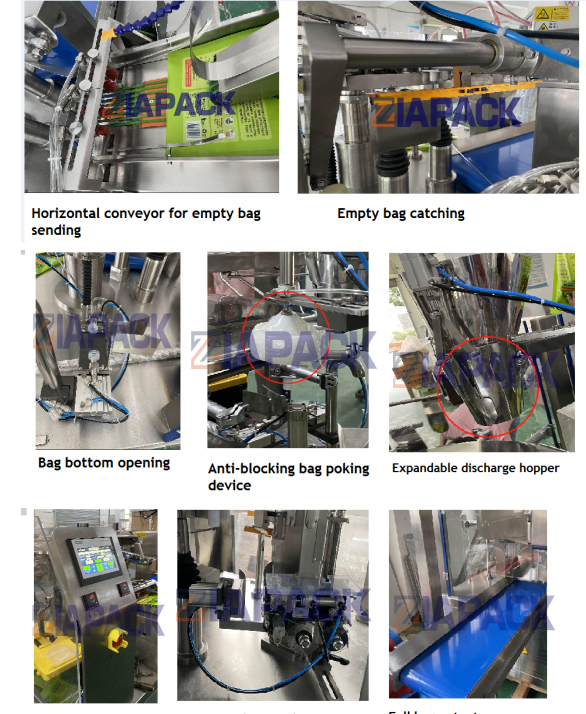

Pre-made pouch fill and seal machine, composed of 8 working stations of efficiency and stability, emphasizes the package of stand-up bag, zipper bag, spout bag, and various pre-made pouches. Cooperated with different dosing systems (combination weigher/ linear weigher/ auger screw/ piston filler) and automatic lifting conveyors, it is widely applied to granules, liquid, and powder.

Features

- Equipped with dosing system to achieve precise product measuring and filling

●Assembled with elevator to lift material automatically

●SIEMENS PLC and touch screen, easy for operation

●Schneider frequency converter and SMC cylinder

●Full 304# stainless steel construction, able to be cleaned by rinsing

●Self-diagnosis: no filling or sealing when it is detected that the bag is not open or not open completely or when there’s lack of bags

●Auto-alarming or stop if there’s something wrong with the air pressure or heating elements

Technical Data

| Model | ZL8-200 |

| Working Stations Number | Eight |

| Pre-made Pouch Types | Heat sealable premade side seal bags, like gusseted bag, flat bottom bags, zipper bags, stand-up bags, spout bags, etc. |

| Pre-made Pouch Size | Width: 120 to 200mm |

| Length: 100 to 350mm | |

| Capacity | 35 to 40bpm (depending on product and pouches) |

| Filling Range | 10 to 2500g (depending on the product) |

| Power Consumption | 2.5kw |

| Air Consumption | 0.6 m³/min (supplied by the user) |

FAQ

Q1: What’s your MOQ?

A: Our MOQ is 1 piece. We can help you to solve the inventory pressure.

Q2: What’s your machine’s application?

A: Our machines are applicable for packaging powder, liquid, paste and granule with different dosing systems. If you do not know what kind of machine are suitable for your products. Please contact us directly or send the inquiry. More detailed information will get more right machine from our recommendation.

Q3: What kind of bag style that your machine can package?

All below bag style we can package. More detailed informations you can contact with our sales online or send inquiry