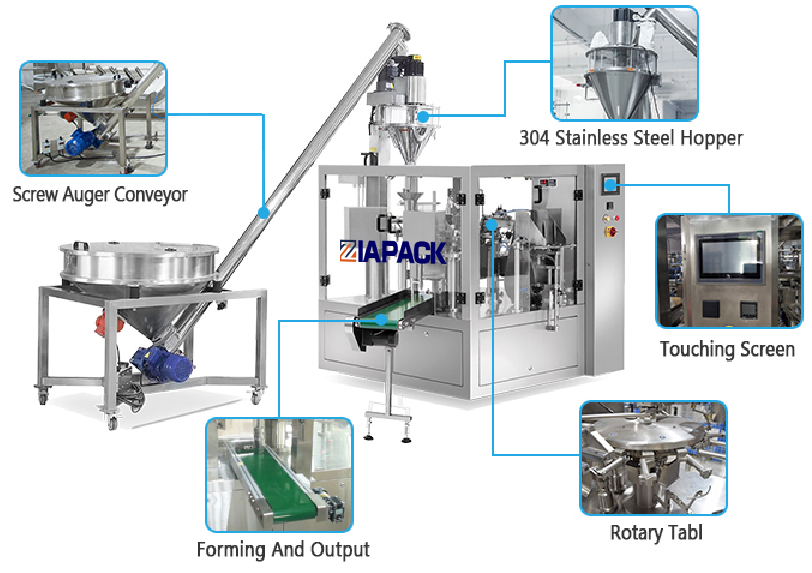

Automatic rotary type packaging machine for pre-made bag for packing different powder material .

Equipped with Augur Filler and Screw Elevator, it is widely applied to packing powder, such as detergent powder, milk powder, flour, spice, coco powder, ground coffee, and so on.

8 work stations

1) bag picking;

2) coding;

3) zip unit;

4) bag opening;

5) according to the material;

6) according to the material;

7) sealing and closing zip;

8) tidy to output;

Features

Saving pouches & less pollution the machine, no pouch or incorrect pouch opening, no fill & no seal

Graphic Interface, Well Arrange, 20 recieption, User Friendly

All IApack rotary packing machine use motor width adjust, change pouch size in a minute.

Low noise vacuum system with pollution free

Washing down by water gun, we follow extremely water proof standard from Korea

Rarely supplier offer this option, we innovate filling the pouch then install center spout in rotary packing machine

With avantage of servo technology, JR series acheive 99% zip pouch open rate

Some pouch can't load by bag stacker, like spout pouch, a horizontal pouch feeder will optioned.

If your package need filling Nitogen, Option in first sealing station will installed this Nitrogen Flushing Device.

Technical Parameters

| Model | ZG8-200 |

| Bag type

| All type of heat sealable preformed side seal bags, fin seal bags, gusseted bags, block bottom bags, zip-lock re-closeable bags, stand-up pouch with or without spout etc. |

| Bag size | W:100~200mm L:100~300mm |

| Filling volume | 5-1500g |

| Capacity | 25-45bags/min (depending on type of product and filling weight) |

| Accuracy | ≤±1 |

| Total power consumption | 3.6Kw |

| Application | Powder and fine granular products such as milk powder, coffee powder, food additives, condiments, tapioca powder, coconut powder, pesticide powder, fertilizer granules etc. |

| Optional equipment | Automatic Auger Filler, Volumetric Cups Filler etc. |

| Note: other specifications available | |

1. we have 24 hours service.

2.One year warranty and Lifelong after sales service.

3.Provide you Quality Control in processing line.

4.OEM service is avaliable,and provide technology supporting in products, we are in 10+ years exporting experience.