Applications

Vertical FF&S Intermittent Motion Bagger, designed for packing products into bags of max width 250 mm, wide range of products like loose food, plastic, metal etc Our machines are capable of producing a considerable variety of bags, for instance: flat bags, bricks, side gusset bags, stabile with 4 sealed corners, euro slot bags, handle etc

- Food loose

- Fresh, frozen

- Granulates

- Sweets

- PET food

- Cookies

- Coated nuts

- Frozen fruits, vegetables

- Metal, plastic parts

Features

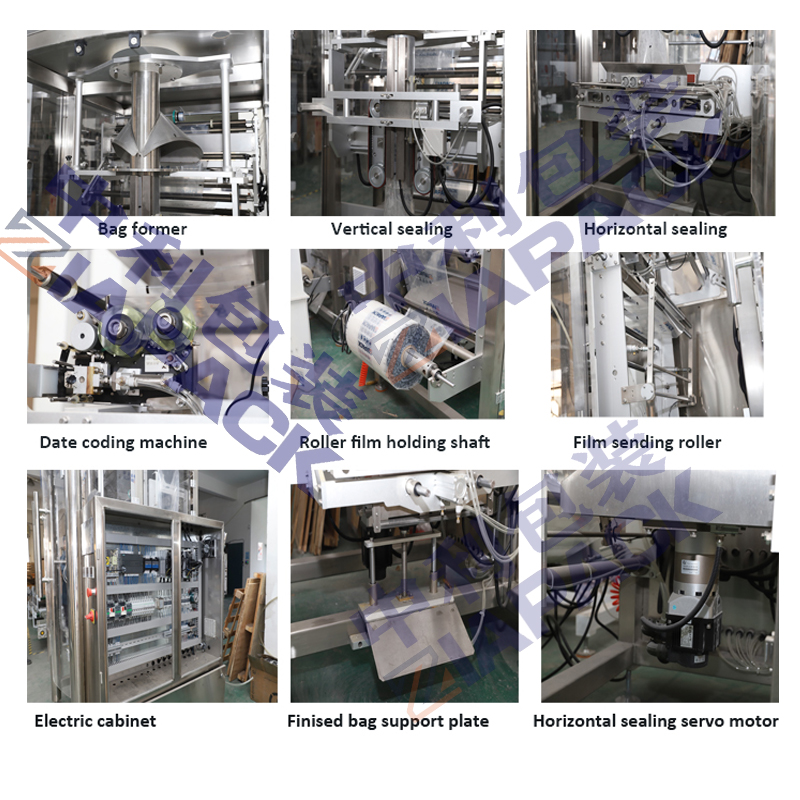

- PLC control with Touch-Screen HMI

- Servo technology with high performance

- Simple and fast bag size changeover without tools

- Precision film auto tracking, length registered by photo-sensor or encoder

- Vacuum pump assists film transport

- Ajustable dwell time for better looking seals and increased packaging speeds

- Compact, robust and long-life construction

Technical Data

| Bag Styles | Pillow Bag |

| Bag Width | 80 to 260mm (3.1 to 10.3") |

| Bag Length | 50 to 340mm (2.0 to 13.4") |

| Product Characteristic | Granules, Powders, Liquids, Pastes |

| Dosing System Compatible | Volumetric Cup , Linear Scale , Multi-Head Scale |

| Running Motion | Continuous |

| Working Efficiency | 120bpm |

| Control By | PLC with HMI Touch Screen |

| Date Coding Can Be | Hot Stamping Coder, Thermal Transfer Coder, Label Applicator |

| Options Available | Perforation, Dust Absorb, Seal PE Film, SS Frame, SS & AL Construction, Nitrogen Flushing |

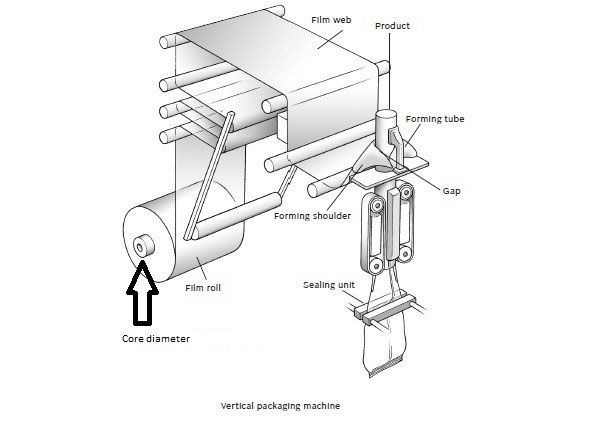

| Film & Reel | 0.04-0.12mm Real Max.Dia.400mm(15.7") Width 540mm (15.7") |

| Power & Voltage | 3.0KW |

| Compress Air | Need 0.6 MPa 0.36 M3 |

| Dimensions | 1650 x 1140 x 1650mm (65.1 x 44.9 x 64.9'') |

| Machine Weight | 800 KGS |

Optional Device

1.Tear notch device

2.Hole punch device.

3.Static eliminator.

4.Gusset device.

5.Date printing.

6.Prevention broken bag device.

7.3 side seal device.

8.Nitrogen gas flushing.

9.Air flushing & Air exhaust device.

10.Heavy product bag support device.

11.PE film sealing device.

12.Prevention broken bag device.