Applications

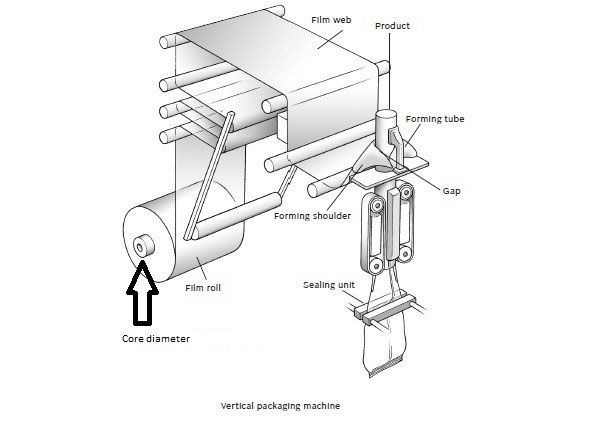

A vertical form fill seal machine is an automatic assembly line product packaging system. Commonly used in the food manufacturing industry, these highly efficient machines create plastic bags out of a flat roll of film, fill the bags with the product, and then seal them.

There are a number of benefits of using a form fill seal machine for packaging food products. They include:

Features

Automating the whole forming, filling, and sealing process

Increasing precision by notifying the equipment operator when an obstruction has led to improper sealing

Decreasing number of rejects

Creating packaging that is more durable and reliable

Speeding up the process, resulting in higher output with lower labor costs

Reducing packaging costs

Ultimately, vertical form fill seal machines are not just quick and efficient, packaging dozens of products per minute; they also provide consistency as the equipment ensures that each package contains exactly the same amount of product.

The use of a form fill seal machine can also extend your product’s shelf life as many food packages can be filled with nitrogen. It is because of the consistency, efficiency, and cost-effectiveness of these machines that many food processing and packaging companies purchase them for their packaging lines.

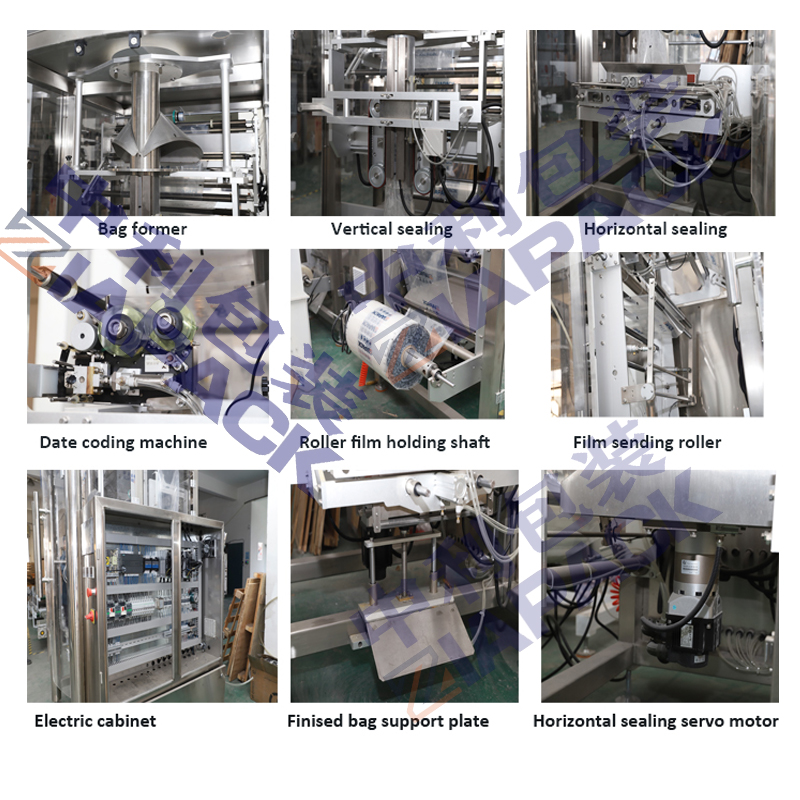

This high-tech machine is one of our most popular bag filling machines for packaging products safely and effectively. The various machines we offer at TDI PACKSYS are great for snack foods, coffee, pet foods, liquids, and more. They feature:

Top of the line componentry

Speeds of up to 70 pouches per minute

Pouches in various sizes and styles, including flat, side gusseted, quad seal and block bottom

Optional valves and tin ties for coffee packaging

Stainless steel or powder coat finish

Nitrogen flushing for extended shelf life products

To learn more about how our packaging automation systems can help your business, contact us and schedule a demo today.

We make a variety of vertical form fill seal machines for snack foods, popcorn, nuts, coffee, pet foods, etc.

Also liquid fill products, including hot and cold fill applications

Many pouch styles and sizes, including pillow, side gusseted, block bottom and quad seal

Optional valves and tin ties for coffee pouch applications

Servo technology for quick and easy single push button size changes (requires additional bag forming sets)

Allen Bradley PLC user interface

Servo assisted film feeding and full servo-driven, heavy duty sealing jaws for optimal speed and accuracy

Stainless steel or powder coat finish

Can be equipped with nitrogen flushing for extended shelf life

Speeds of up to 70 pouches per minute

Optional components to create a complete system, including multi-head or linear scales

Technical parameters

| Model | ZL420 |

| Bag Type | Pillow bag, Gusseted bag/Flat bottom bag |

| Operation Mode | Intermittent |

| Speed | Up to 40 bags/min |

| Bag Length | 50-280mm |

| Bag Width | 70-180mm |

| Reel Film Width | 420mm |

| Film Thickness | 0.04-0.12mm |

| Reel Outer Dia | Ф350mm |

| Reel Inner Dia | Ф75mm |

| Voltage | AC 220V/ 50HZ,1phase or per customer needs |

| Power Consumption | 3KW |

| Compressed Air Requirement | 0.6MPa,0.36 M3 / Min |

| Machine Size | 1480x1020x1400mm(L x W x H) |

| Weight | 700KG |