Automatic Liquid & Oil Packaging Machine

Applications

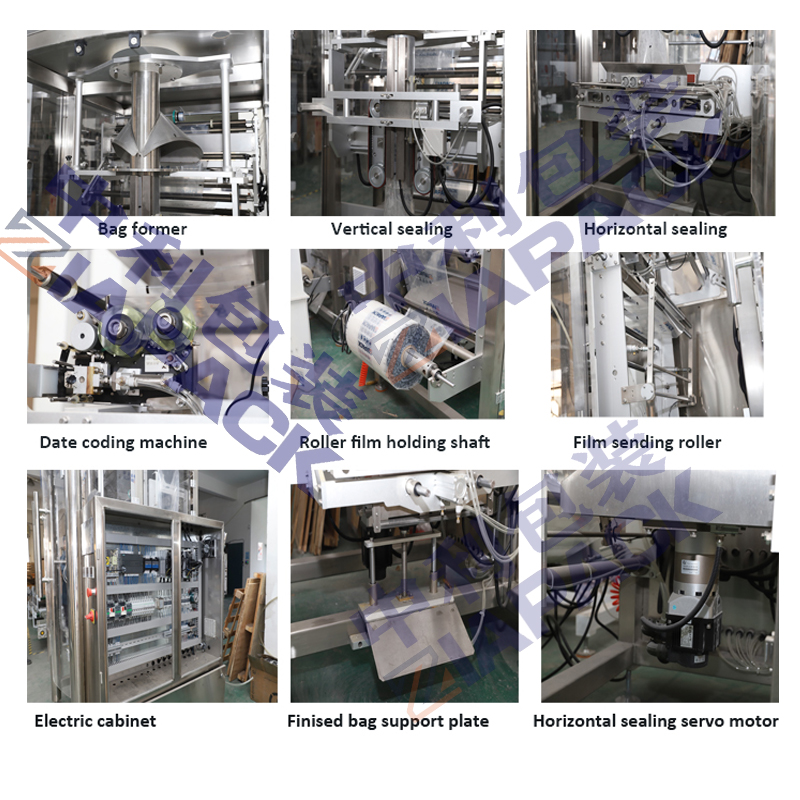

This unit machine is special design for packaging liquid& sauces product into plastic bag .The machine have the function of automatic bag forming, Liquid product measuring and filling .With optional function of exhausting the air inside the bag and then sealing the bag .The machine also have color ribbon for date printer for coding of expiry date and production date.Widely use for packaging different liquid and paste product

The whole machine unit including the liquid hopper ,transfer pump and connect pipe and meausring filling pump and vffs packaging machine .

unit are using for filling medium or high viscosity liquid products . The machine has a storage hopper, electronic control and ZVF-200 packaging units, the structure is simple, operation is convenient; Pneumatic parts adopt Germany and Japanese SMC FESTO pneumatic components; Cylinder piston and cylinder body are made of PTFE and 316 l stainless steel materials, in line with the GMP requirements; Filling volume and filling speed can be adjusted With high precision; Drip tight, prevent wire filling device for the filling cocks; The machine can be modified according to customer requirements into explosion-proof filling system; Multi-head filling; Thermal insulation system; Semi-automatic or fully automatic filling system.

Features

- English and Chinese screen display, operation is simple.

- PLC computer system, function is more stable, adjustment any parameters not need stop machine.

- It can stock ten dispose, simple to change variety.

- Sever motor drawing film, position accurately.

- Temperature independent control system, precision get to±1°C.

- Horizontal, vertical temperature control, suitable for various of complex film, PE film packing material.

- Packing type diversification, pillow sealing, standing type, punching etc.

- Bag–making, sealing, packing, print date in one operation.

- Work circustance quiet, low noise.

Technical Specifications

| Model | ZL-320 | ZL -420 | ZL -520 | ZL -720 |

| Measuring Range | 150 ~ 800ml | 150-1500ml | 150~2000mL | 150~4000ml |

| Packaging Speed | 5 ~ 70bags/min | 5-60bags/min | 10~50bags/min | 10~40bags/min |

| Bag Width | 50 ~ 150mm | 60-200mm | 80~250mm | 100350mm |

| Bag Length | 80 ~ 240mm | 80-300mm | 80~350mm | 100~450mm |

| Film Roll Width | Max.320mm | Max.420mm | Max:520mm | Max:720mm |

| Machine Size | (L)1185 x (W)935 x (H)1245mm | (L)1217 x (W)1015 x (H)1343mm | (L)1488*(W)1080*(H)1490mm | (L)1716*(W)1260*(H)1820mm |

| Machine Weight | 550KG | 650KG | 750KG | 900KG |

Main electric parts

| ARTS | SUPPLIER |

| PLC | Panassonic |

| Touch Screen | Weinview |

| Servo Motor | Panassonic |

| Servo Driver | Panassonic |

| Solid state Relay | Crydom |

| Intermediate Relay | Omron, IDEC |

| Switching power supply | Schneider |

| Air Cylinder | AIRTAC |

| Gear Motor | V.T.V |

| Electromagnetic Valve | SMC |

| Pneumatic FRL | SMC |

| Sensors & controllers | AUTONICS |

Packaging Detail:Exported woodencase

Delivery Time: 35days after confirming order