Applications

Its suitable to use in packing the high accuracy and easy fragile material , such as : puffy food , crispy rice , Potato Chips , Snacks , candy , pistachio , sugar , apple slices , dumpling , chocolate , pet food , small wares etc .

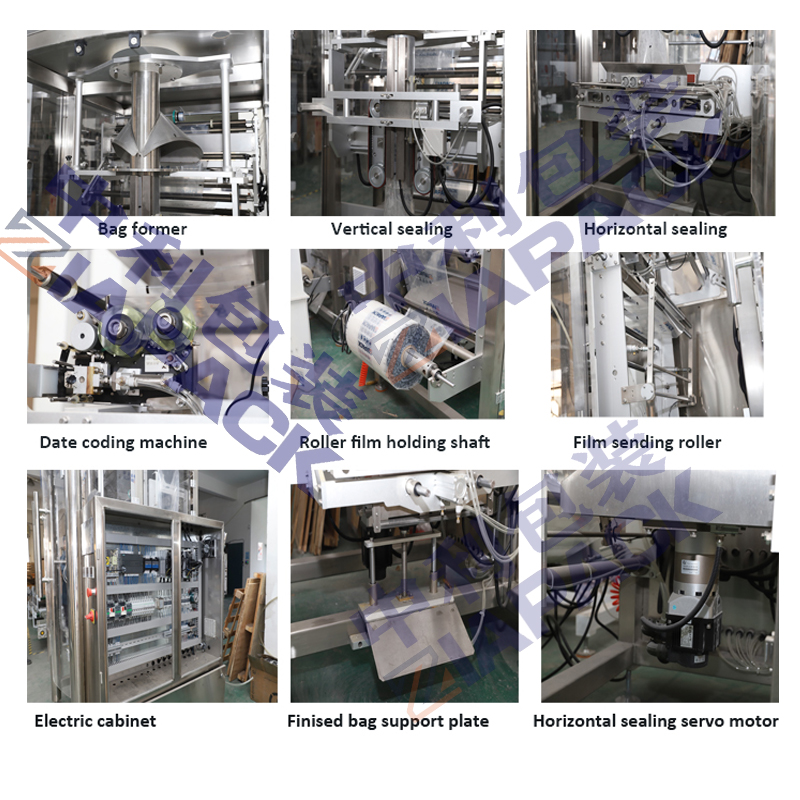

Features

*The four sides sealing filling mchine is added on the packaging bag based on vertical bag,make the packaging bag have a stronger spatial vision,nice apperance and more attraction.

*PLC control with touch panel-step by step instruction.

* equipped with servo winding system,pneumatic control system.

*use intellectual temperature controller,the high temperature control to ensure neat sealing.

* the perfect automatic alarm safety protection,little waste,the machine will automatically complete all packaging processes from feeding,measuring ,filling,printing,finished bag.

- Serviceability and cleanability made easy and quick with dual (left and right) access to inside working as well as the unobstructed film path and film sealing.

- Tool-less removable vacuum pull belts

- Stainless steel constructed machine with anodized aluminum side plates for film unwinding system to maintain long term value.

- Servo drives on both the pull belts and sealing jaws provide complete digital control to optimize speed and accuracy.

- Precise control of seal jaw travel optimizes productivity and is ideal when running slim profile bags.

- Open design allows for easy film threading from back to front of the machine and around the forming tube. Air shafts eliminate the need for side chucks on film shaft.

Technical Data

| Model | ZL520 |

| Packing speed | 35bag/min |

| Bag size | front width:70-180mm ,side width:60-80mm

|

| Bag making mode | Flat bottom bag /pillow bag |

| The maximum width of packing film | 520mm |

| Thickness of film | 0.04-0.08mm |

| Air consumption | 200L/min 0.7×105Pa |

| Main power/voltage | 4.5KW/220V 50-60Hz |

| Dimension | 1600×1400×2000mm |

| The weight of switchboard | 750kg |