Applications

All kinds of gains and solids, like candy, nuts, raisins, peanuts, melon seeds, nuts, potato chips, chocolate, biscuits and so on.

Performance and features

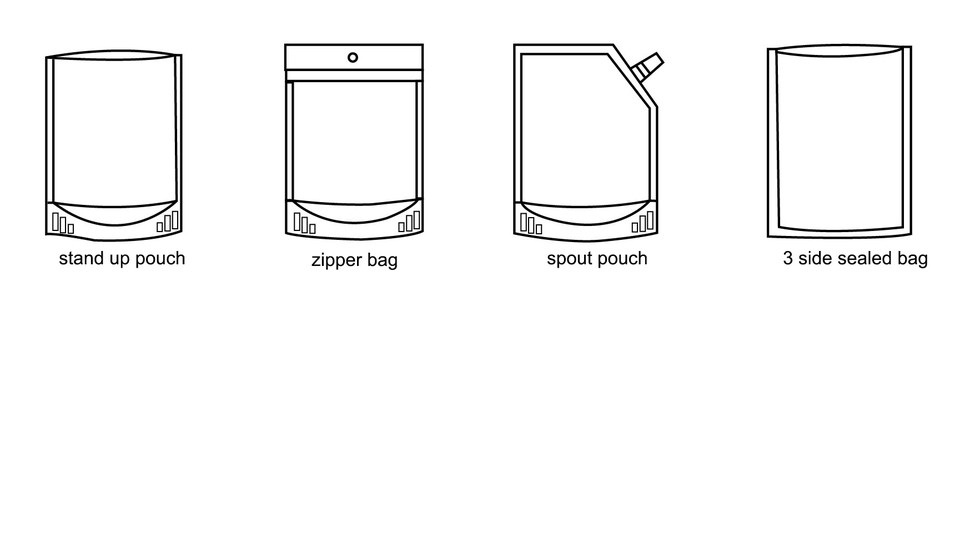

1.wide applications: various state and nature of solid (granule);

2.A wide range of pouches: all kinds of pre-made pouches;

3.Easy to operate: PLC controller, HMI system makes easy operation;

4.Easy to adjust: change different pouches within 10 minutes;

5.High automation: unmanned in weighing and packing process, machine alarm automatically when failure;

6.Perfect prevention system: when the bag is not opened or not opened completely, it will be non-filling and non-sealing, so the bags can be reused and the product is not wasted thus save the production cost;

7.The product contact parts are adopted SUS304 to ensure sanitation and safety, meet the GMP standard;

8.Imported engineer plastic bearings, no need to oil, no contamination;

9.Vacuum generator: low consumption, high efficiency, cleaness, and long useful life;

10.Pre-made bag packing:perfect sealing quality, upgrade the finished product.

Technical parameters

| Equipment model | ZL6-200, ZL8-200 |

| Equipment material | 304 stainless steel |

| Pneumatic component | SMC,AirTAC |

| Vacuum component | Vacuum generator (SMC) |

| Drive mode | Frequency conversion motor drive |

| Measuring type | Multi-head computer weigher |

| Operation interface | Touch screen(double language:Chinese and English) |

| Bag materials | Heat sealable film as PA/PE,PET/PE,AL film etc. |

| Bag size | W:70~200mm L:100~300mm (date coding requires≥140mm length) |

| Filling range | 5~1500g |

| Packing speed | 20~55bags/min (depended on the product and filling weight) |

| Package accuracy | Error≤±1% |

| Weight | ZL6-200:800kg |

| ZL8-200:1000KG | |

| Dimension | ZL6-200:1475*1325*1480(L,W,H) |

| ZL8-200:1635*1455*1480(L,W,H) | |

| Total power | ZL6-200:1.5kw |

| ZL8-200:2.3kw | |

| Driving power source | 380V Three-phase Five-line 50HZ |

| Control power source | DC24V |

| Compress air requirement | ≥0.45m³/min (compress air is provided by user) |