This Pre-made pouch fill and seal machine composed of 8 working stations of efficiency and stability, emphasizes the package of stand-up bag, zipper bag, spout bag, and various pre-made pouches. Cooperated with auger screw and automatic lifting conveyors, it is applied to powder material.

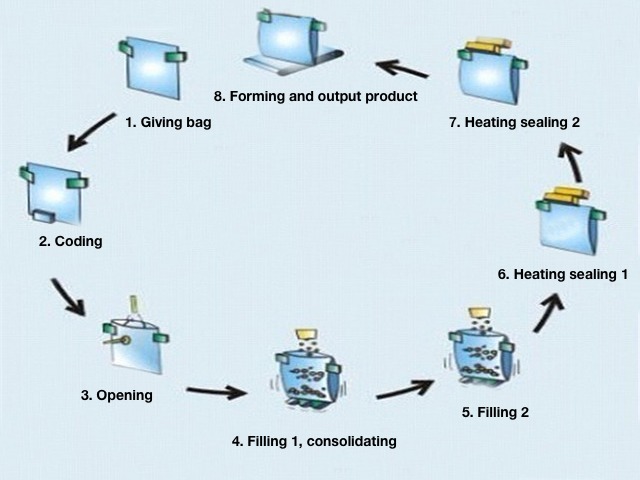

Working Stations

Some of the working stations in the left sketch are optional and customizable.

Take zipper bag as an example as below:

- 1st bag feeding station

- 2nd code printing station

- 3rd zipper opening station

- 4th product filling and vibrating station

- 5th zipper closing station

- 6th buffering and dust cleaning station

- 7th bag sealing station

- 8th bag forming and outputting station

Features

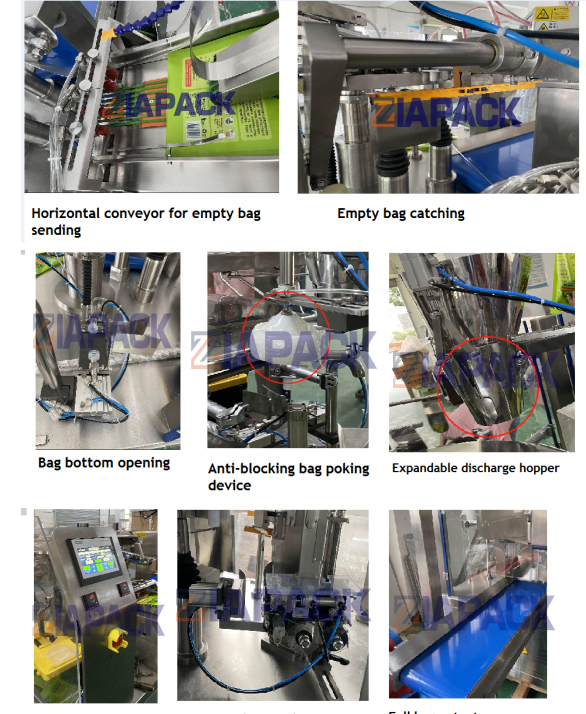

- Saving pouches & less pollution the machine, no pouch or incorrect pouch opening, no fill & no seal.

- Graphic Interface, Well Arrange, 20 recieption, User Friendly.

- All iapack rotary packing machine use motor width adjust, change pouch size in a minute.

- In case of door opened, machine stop to protect user.

- Low noise vacuum system with pollution free.

- Washing down by water gun, we follow extremely water proof standard from Korea.

Technical Data

- Pouch Type:Spout Bag, Zipper Bag, Pillow Bag, 3 Side Bag, 4 Side Bag

- Working Station:8 Working-Station

- Filling Range:5-1500g

- Pouch Width:80-240mm(3.15”-7.87”)

- Pouch Length:100-300mm(3.94”-11.8”)

- Capacity:Up to 50 Bags/Min(Depends on products’ natures and filling weight)

- Dosing System:Auger Filler

- Power Supply:Per customer specification

- Power Consumption: 3.5KW

- Compressed Air:400 L/Min. Zip Function 580 L/Min.

- Machine Dimension:2000x1200x1400mm (78.7'x47.2'x55.1')

- Machine Weight:1850Kg